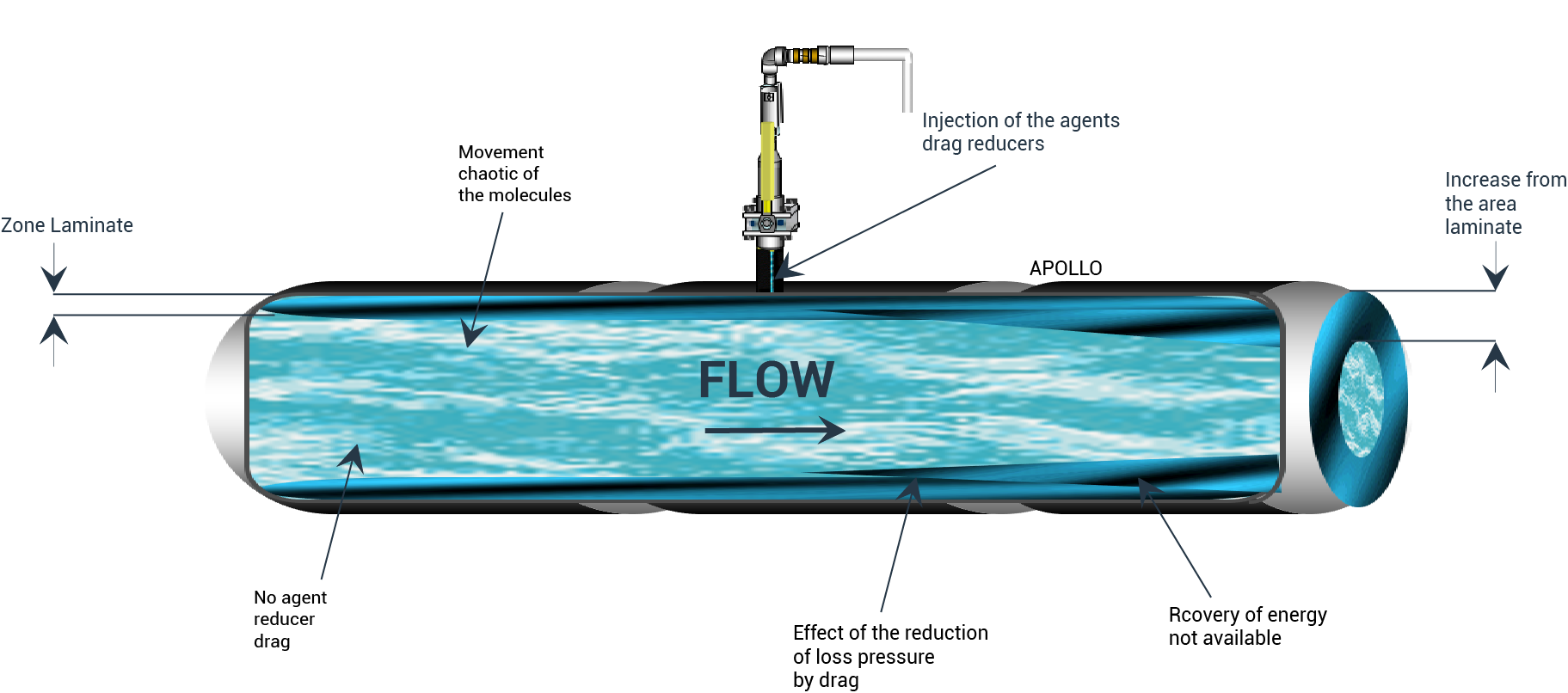

1. INCREASED FLOW

With more than 20 years of experience with Friction Reducing Agents, Quimica Apollo has obtained satisfactory results in more than 20 pipelines with diameters ranging from 6″ to 30″ and lengths ranging from 60 kms to more than 400 kms. In the PEMEX transport network, flow has increased from 20% to 100%. This was achieved through the use of Apollo Friction Reducing Agents.

2. PRESSURE REDUCTION

For a pipeline that runs through a densely populated city like Mexico City. It was necessary to decrease its operating pressure to increase the level of safety of the population, with the injection of reducing agents. Apollo has managed to reduce the line pressure up to 20%

3. ENERGY SAVING

A hydrocarbon pipeline in the Southeast of Mexico, the user had to increase operational reliability and saving gas consumption in their pumping systems; with the application of Apollo friction reducing agents, up to 10% was saved.

4. OPERATIONAL OPTIMIZATION

In a polyduct consisting of 8 PEMEX re-pumping stations, a station suffered severe damage to its dynamic pumping system, with the injection of friction reducing agents, it was possible to replace the station while preserving the transport flow.